Grounded

Calcium Carbonate

Product Overview

Ground Calcium Carbonate (GCC) is a premium, naturally derived mineral produced from carefully selected, high-purity limestone. Through advanced processes of crushing, fine grinding, and precise particle size classification, GCC delivers consistent quality, exceptional whiteness, and excellent chemical stability. Its naturally low abrasiveness and high brightness make it an ideal choice for a wide range of industrial and commercial applications.

As a versatile functional filler and extender, GCC plays a critical role in enhancing product performance while optimizing formulation costs. It improves mechanical strength, opacity, surface smoothness, and processing efficiency, enabling manufacturers to achieve superior end-product quality without compromising economics. The controlled particle size distribution ensures excellent dispersion and compatibility across various matrices, contributing to uniformity and reliability in final applications.

Due to its cost-effectiveness, environmental friendliness, and performance-enhancing properties, Ground Calcium Carbonate is widely utilized in industries such as plastics, rubber, paper, paints & coatings, adhesives & sealants, construction materials, and pharmaceuticals. Its ability to balance performance, aesthetics, and sustainability makes GCC an indispensable raw material in modern manufacturing.

Manufacturing Process of Ground Calcium Carbonate (GCC)

The production of Ground Calcium Carbonate (GCC) follows a carefully controlled, multi-stage process designed to ensure high purity, consistent particle size, and reliable performance across applications.

1. Selection of High-Grade Limestone

The process begins with the careful selection of high-purity, naturally occurring limestone deposits. Only limestone with optimal calcium carbonate (CaCO₃) content, high whiteness, and low impurity levels is chosen. This ensures superior brightness, chemical stability, and performance in end-use applications.

2. Primary and Secondary Crushing

Selected limestone blocks are first reduced in size through primary crushing, typically using jaw crushers, to break large rocks into manageable fragments. This is followed by secondary crushing, where the material is further reduced to a uniform size suitable for fine grinding. This stage ensures efficient milling and consistent downstream processing.

3.Fine Grinding (Ball Mill / Vertical Mill)

The crushed limestone is then processed through advanced grinding systems, such as ball mills or vertical roller mills. During this stage, the material is ground to precise micron or sub-micron particle sizes. The grinding parameters are carefully controlled to achieve the desired fineness, shape, and surface area, which are critical for product performance.

4. Air Classification for Particle Size Control

After grinding, the material passes through a high-efficiency air classification system. This step separates particles based on size, allowing precise control over particle size distribution. Oversized particles are recycled back to the grinding stage, ensuring consistency and uniformity in the final product.

5. Quality Inspection and Testing

Each batch undergoes strict quality inspection to verify particle size distribution, whiteness, moisture content, and chemical purity. Advanced laboratory testing ensures that the product meets industry standards and specific customer requirements before approval.

6. Hygienic Packaging

The finished GCC is packed in clean, contamination-free environments using moisture-resistant and durable packaging. Hygienic handling and secure packaging preserve product quality during storage and transportation.

Chemical Specifications of Ground Calcium Carbonate (GCC)

Ground Calcium Carbonate (GCC) is manufactured to meet stringent international quality standards, ensuring consistent performance, purity, and safety across diverse industrial applications. Each specification is carefully monitored and tested using globally recognized methods.

Chemical Name: Calcium Carbonate

Calcium Carbonate is a naturally occurring inorganic compound widely used as a functional filler and extender. Its chemical stability and compatibility with various formulations make it a preferred raw material in industrial applications.

Chemical Formula: CaCO₃

The chemical formula CaCO₃ confirms the material’s composition, ensuring compliance with international chemical identification standards and consistent performance in processing and end-use applications.

CaCO₃ Content: ≥ 94 – 98%

A high calcium carbonate content indicates superior chemical purity. Levels within this range meet international standards for industrial-grade GCC, ensuring minimal impurities and enhanced mechanical, optical, and processing properties.

Appearance: White Powder

GCC appears as a fine, free-flowing white powder, reflecting its high purity and controlled processing. The uniform appearance is essential for consistent dispersion and aesthetic quality in finished products.

Whiteness: ≥ 95%

High whiteness is a critical parameter measured using standardized reflectance methods. A whiteness value of ≥95% ensures excellent brightness, color consistency, and opacity, particularly important for applications in paints, plastics, paper, and coatings.

Moisture Content: ≤ 0.5%

Low moisture content is essential for maintaining product stability, flowability, and shelf life. A maximum of 0.5% moisture complies with international handling and storage standards, minimizing caking and processing issues.

pH (10% Slurry): 8.0 – 9.5

The slightly alkaline pH range confirms the chemical stability of GCC. This pH level is compatible with most industrial formulations and helps prevent corrosion, degradation, or adverse reactions during processing.

Insoluble Matter: ≤ 0.2%

Low insoluble content indicates minimal presence of unwanted minerals or contaminants. This specification aligns with international purity requirements and ensures smooth processing, improved dispersion, and consistent end-product quality.

Oil Absorption: 18 – 25 g/100 g

Oil absorption reflects the material’s surface area and particle morphology. Values within this range indicate good binding capacity, dispersion, and formulation efficiency, making GCC suitable for use in polymers, paints, rubber, and coatings.

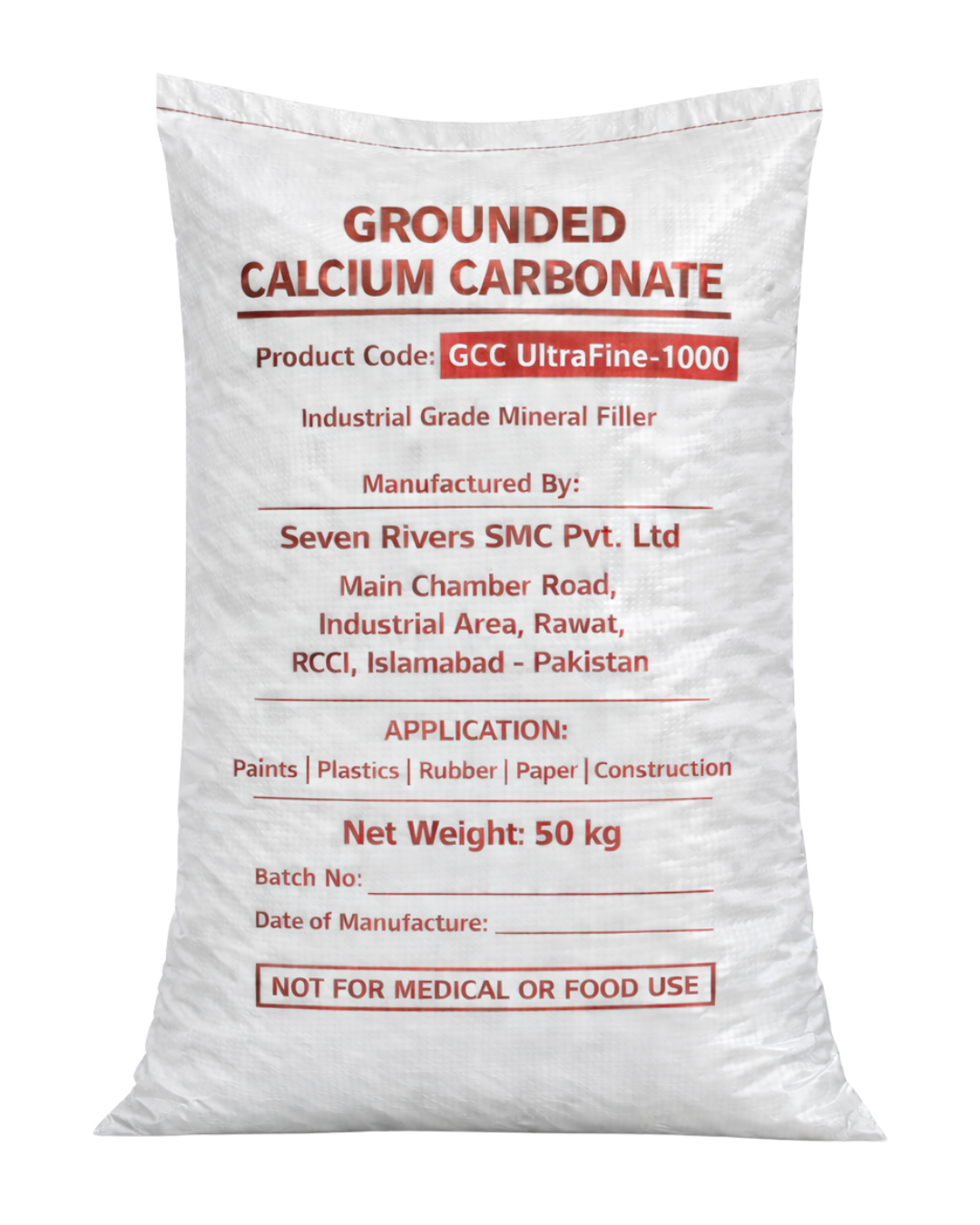

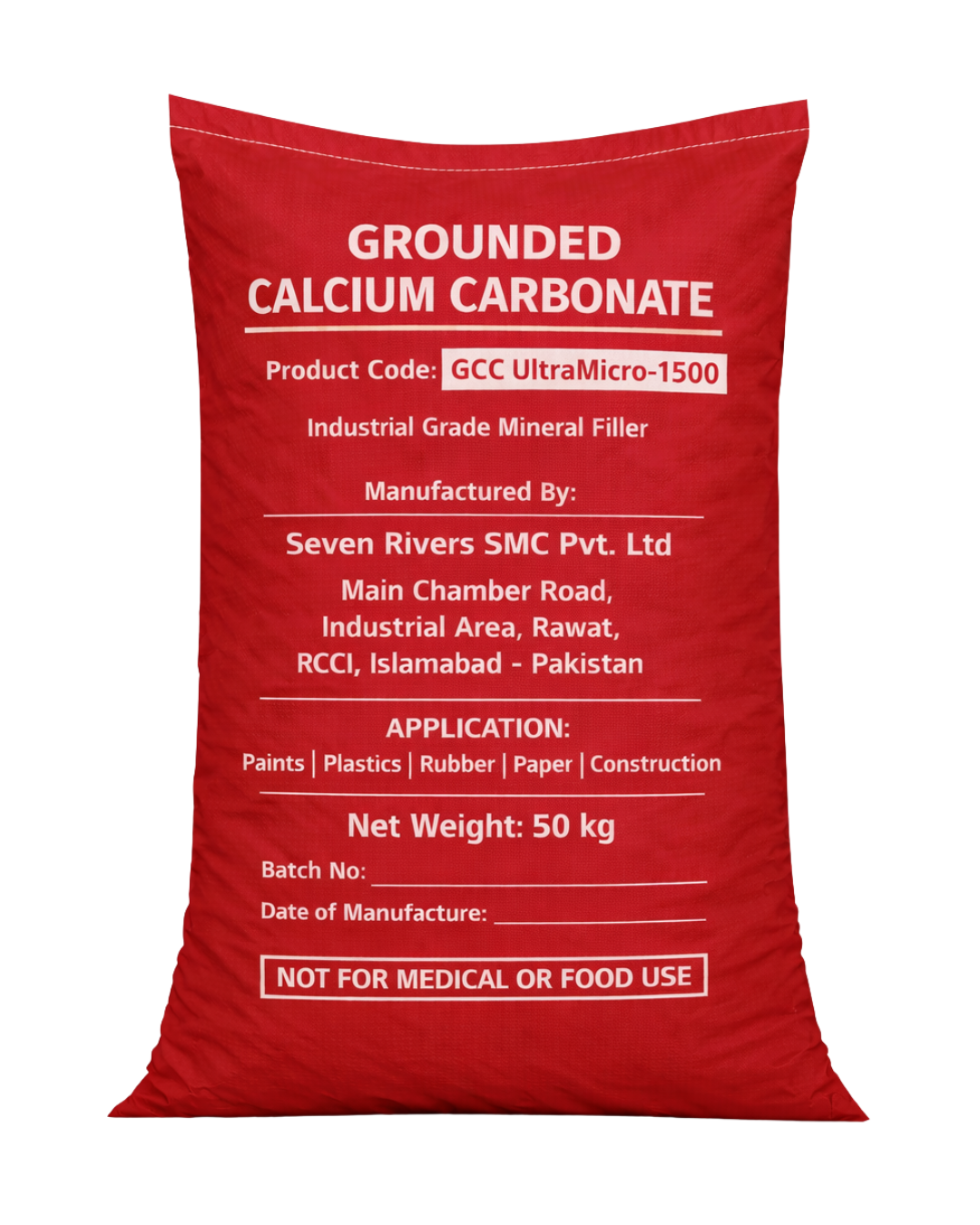

Packing Options

PP / HDPE Bags: 25 kg

PP / HDPE Bags: 50 kg

Customized Packing: As per buyer requirement

Incoterms

FOB – Free On Board

CFA – Cost and Freight

CIF – Cost, Insurance and Freight

Container Load Details

20-ft Container: up to 25–28 MT (metric tons)

40-ft Container: up to 26–28 MT (metric tons)

Depending on packaging and shipping line limits.

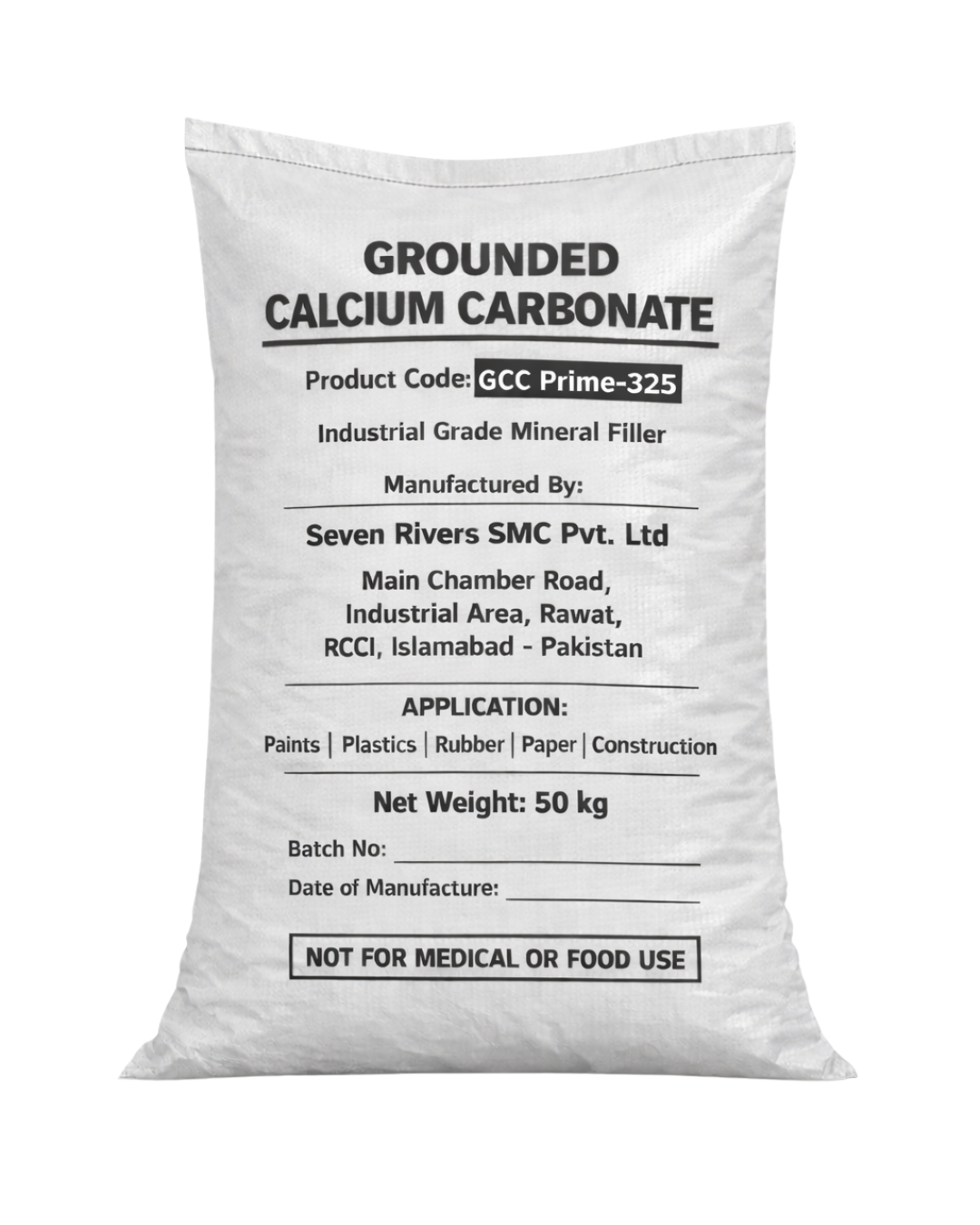

GCC-Prime 325

Pink salt, often called Himalayan salt, is a mineral-rich salt with a characteristic pink hue.

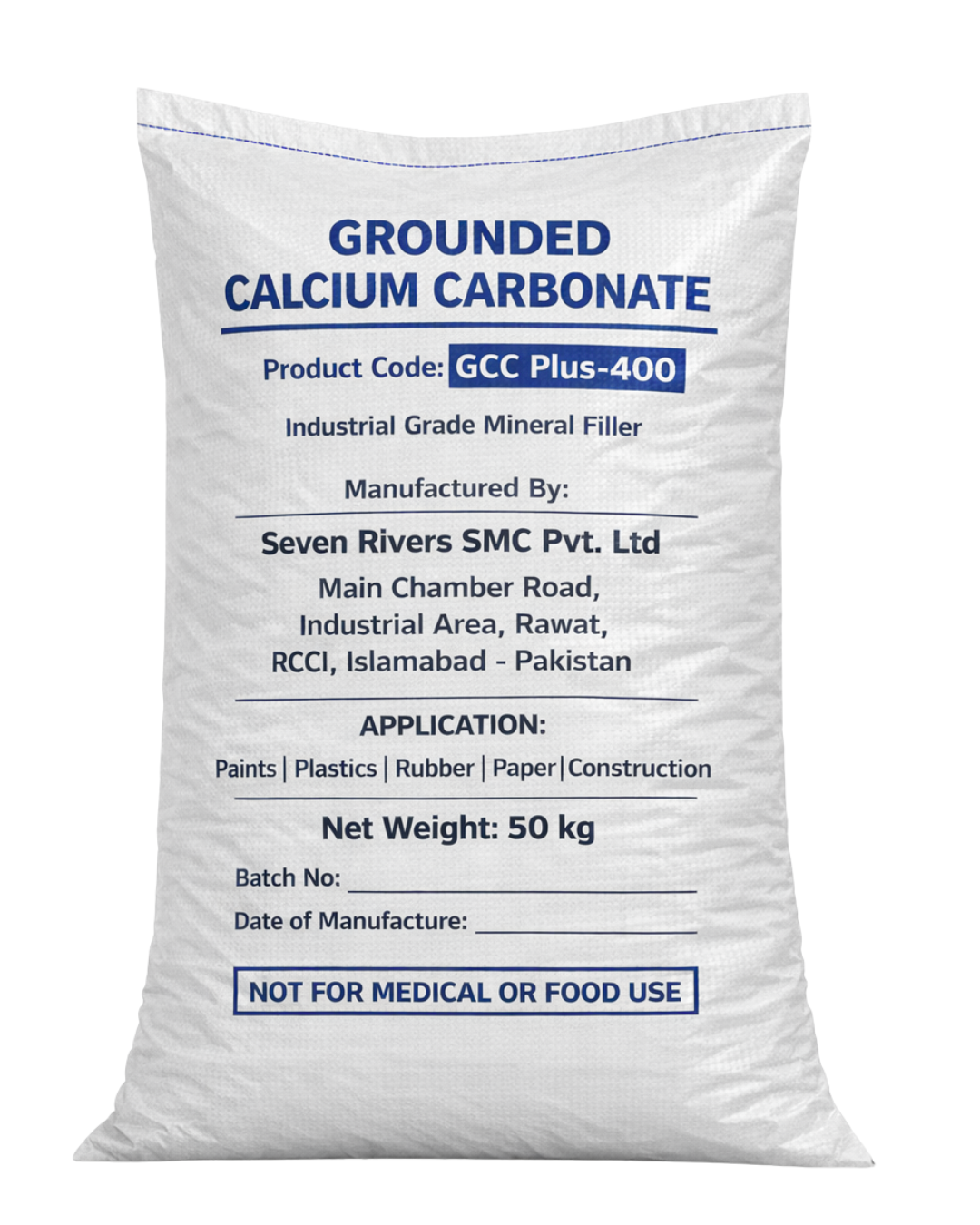

GCC-Plus 400

Pink salt, often called Himalayan salt, is a mineral-rich salt with a characteristic pink hue.

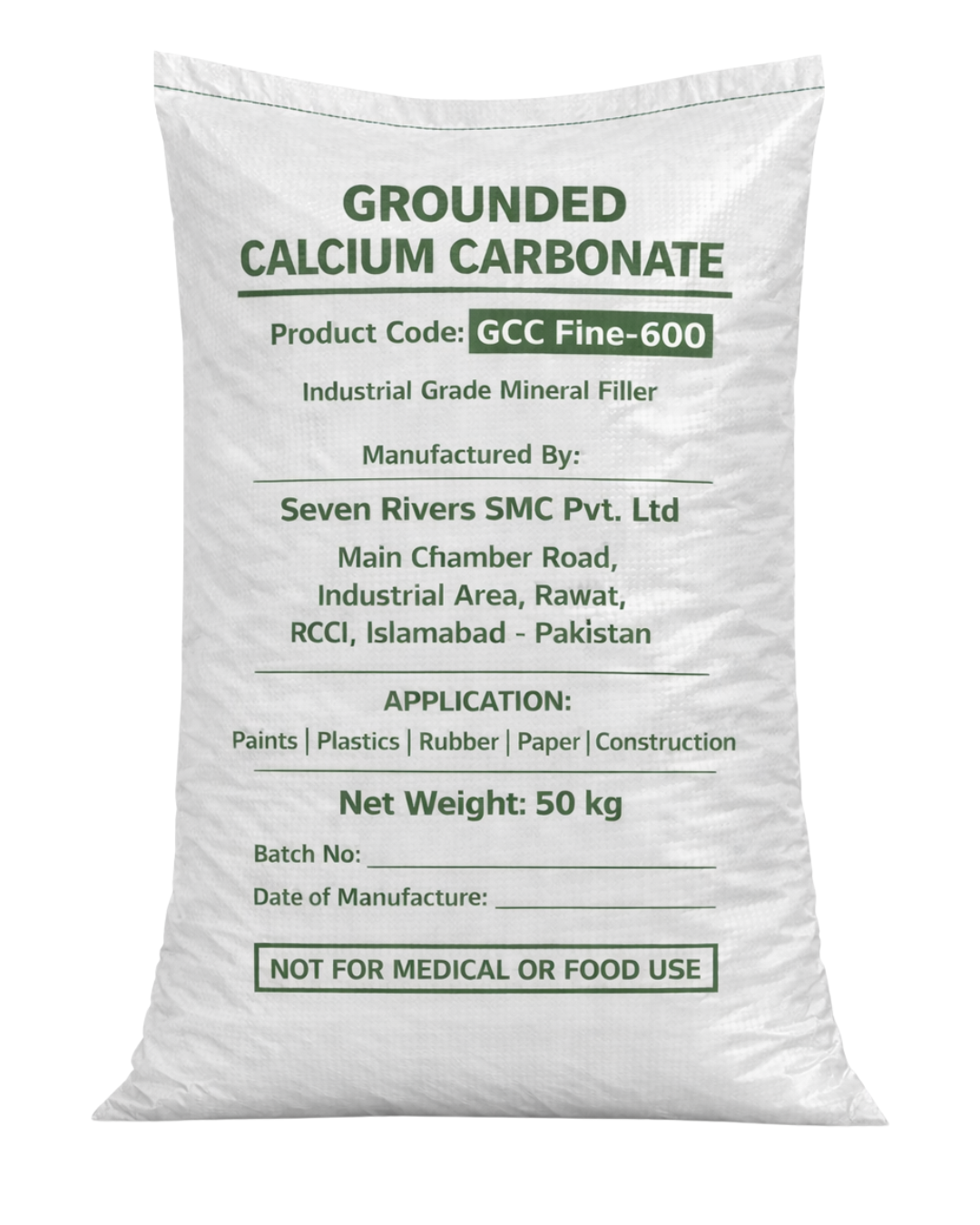

GCC-Fine 600

Pink salt, often called Himalayan salt, is a mineral-rich salt with a characteristic pink hue.

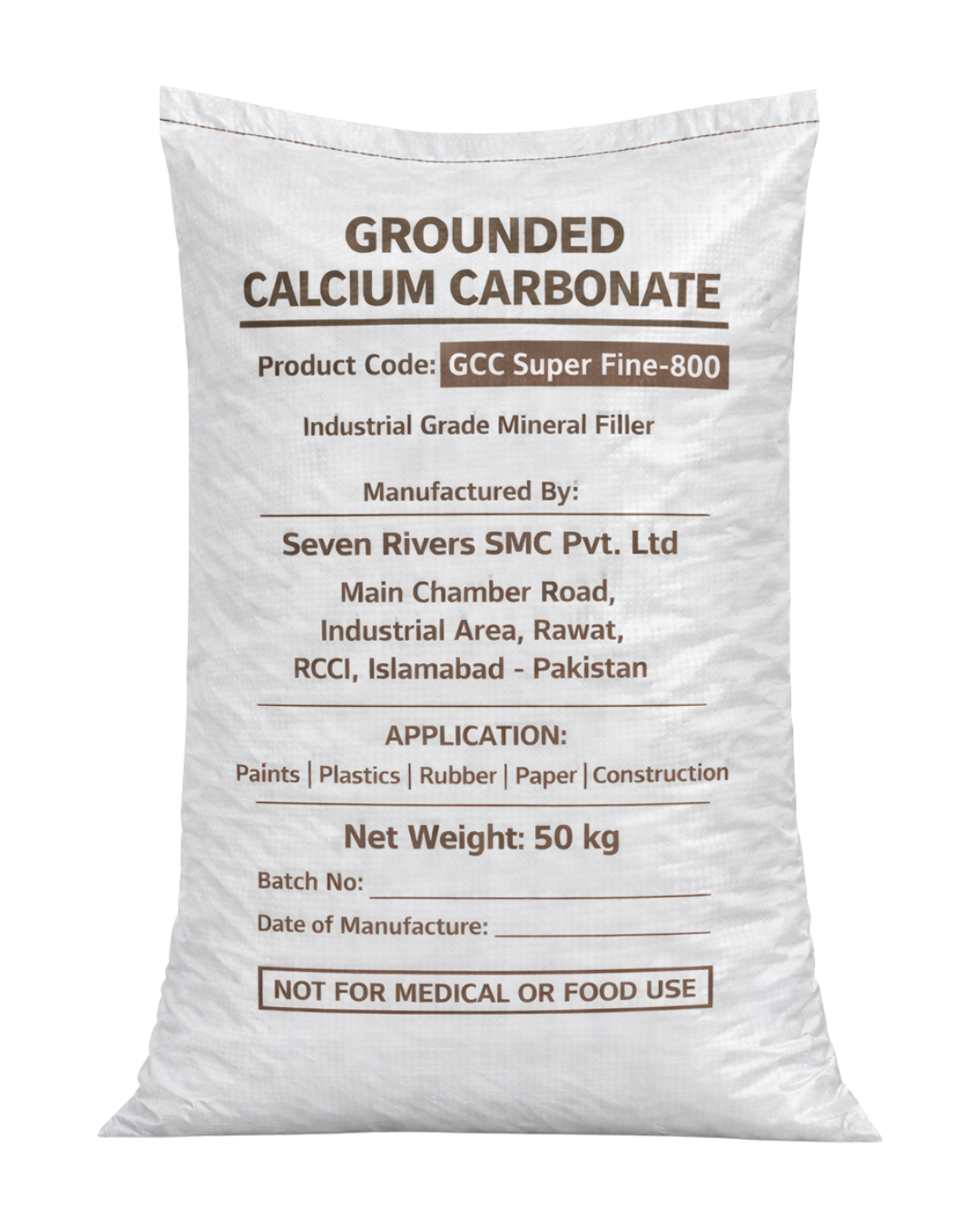

GCC-Super Fine 800

Pink salt, often called Himalayan salt, is a mineral-rich salt with a characteristic pink hue.

GCC-Ultra Fine 1000

Pink salt, often called Himalayan salt, is a mineral-rich salt with a characteristic pink hue.

GCC-Micro Fine 1250

Pink salt, often called Himalayan salt, is a mineral-rich salt with a characteristic pink hue.

GCC-Ultra Micro 1500

Pink salt, often called Himalayan salt, is a mineral-rich salt with a characteristic pink hue.

Contact Us !

We’d be happy to hear from you.

For product inquiries, bulk orders, technical details, or export opportunities, please reach out to our team and we will respond promptly.

Please fill out the inquiry form below with your requirements.

Our sales and technical team will contact you shortly with detailed information and pricing.